HOJA: Qualität und Geschmack seit 1982.

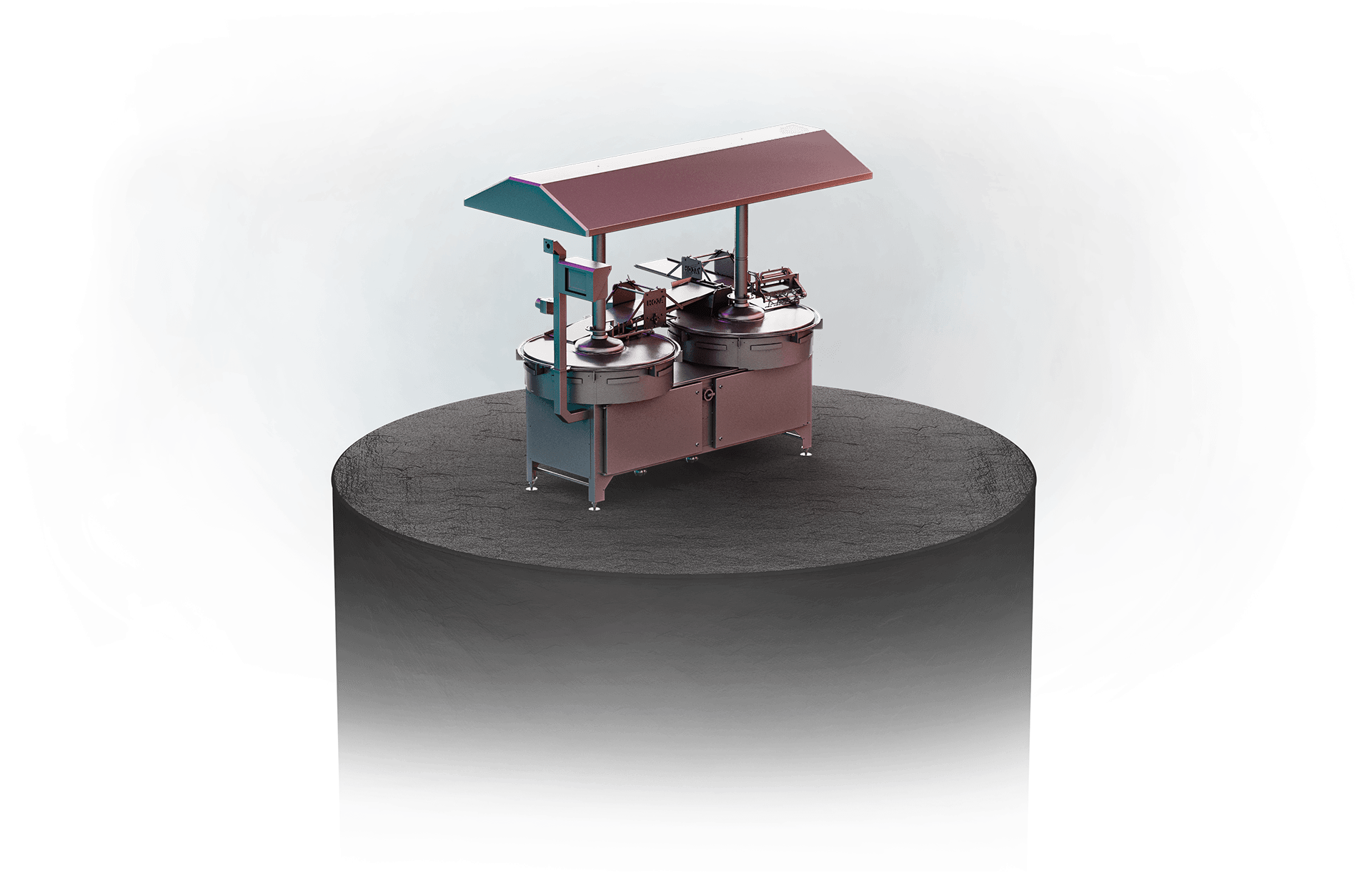

Seit 1982 entwickelt, fertigt, liefert und montiert HOJA Komplettlösungen für Industrie-Bratanlagen in bester „Made in Germany“-Qualität.

Das Besondere: Wo andere Hersteller auf beschichtete Kunststoffbänder setzen, haben wir uns auf die Küche unserer Kindheit besonnen und Braten ausschließlich auf gusseisernen Pfannen.

Das Ergebnis kann sich nicht nur sehen und schmecken lassen, sondern macht sich auch in der höheren Produktausbeute und dem geringeren Wartungsbedarf der Anlagen bemerkbar.

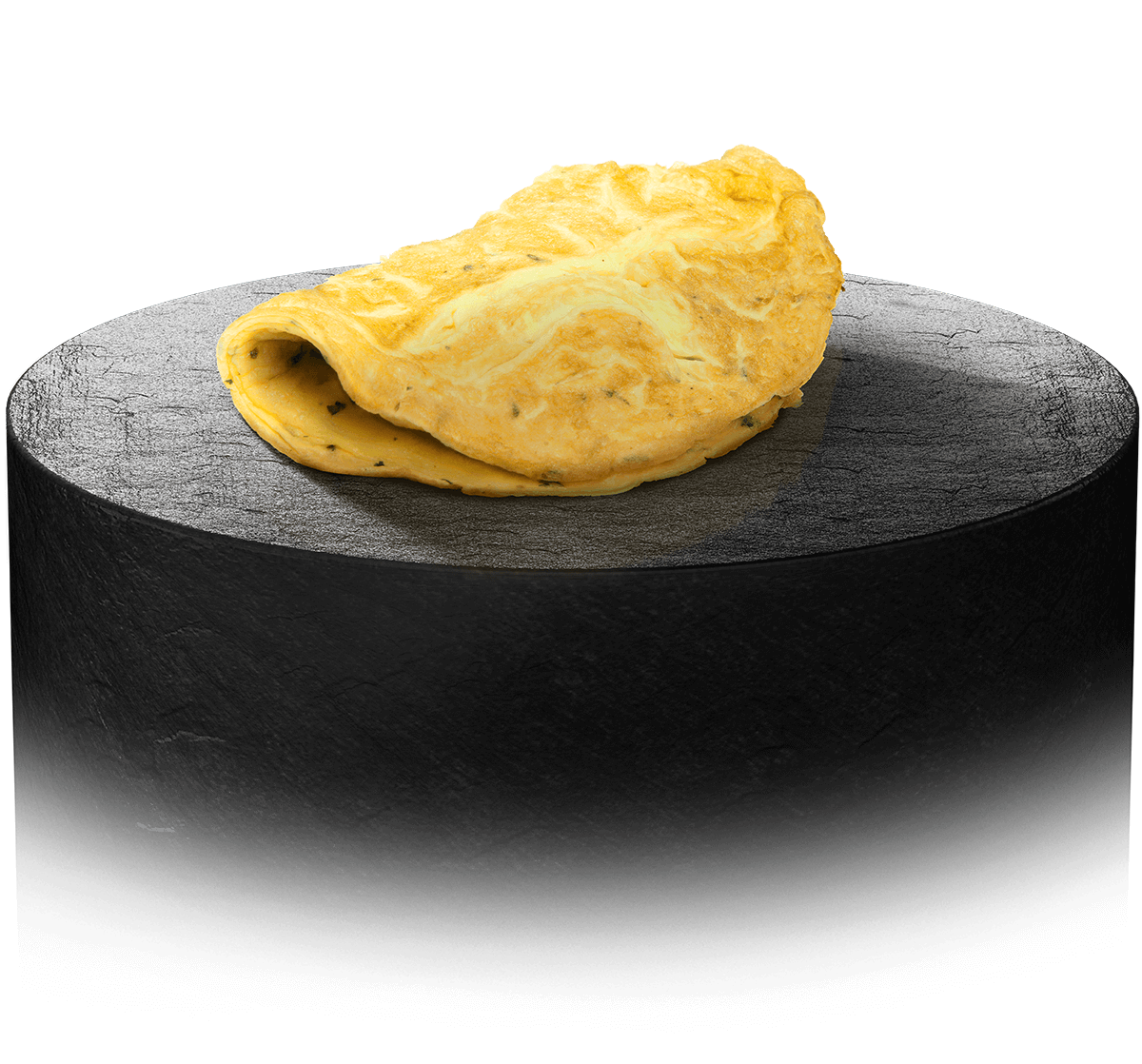

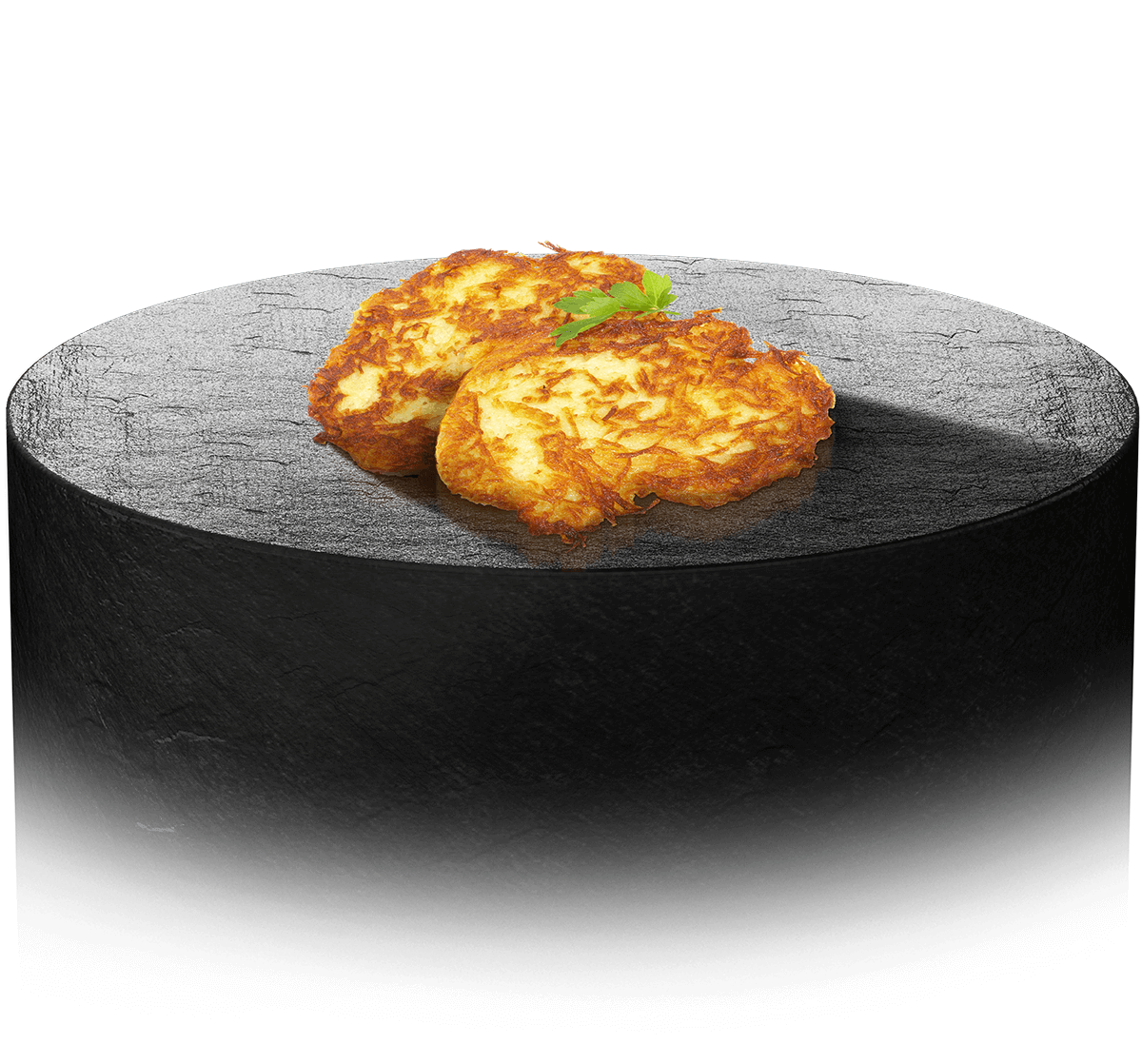

HOJA-Anlagen: Der „Place to be“ für alles, was man braten kann.

Ob Großküche oder Nahrungsmittelindustrie – mit unseren vielfältigen Produktionslinien haben wir immer die perfekte Lösung für Ihre Anforderungen. Und auch wenn es mal spezieller wird, fertigen wir individuelle Sonderlösungen nach Ihren Vorstellungen.

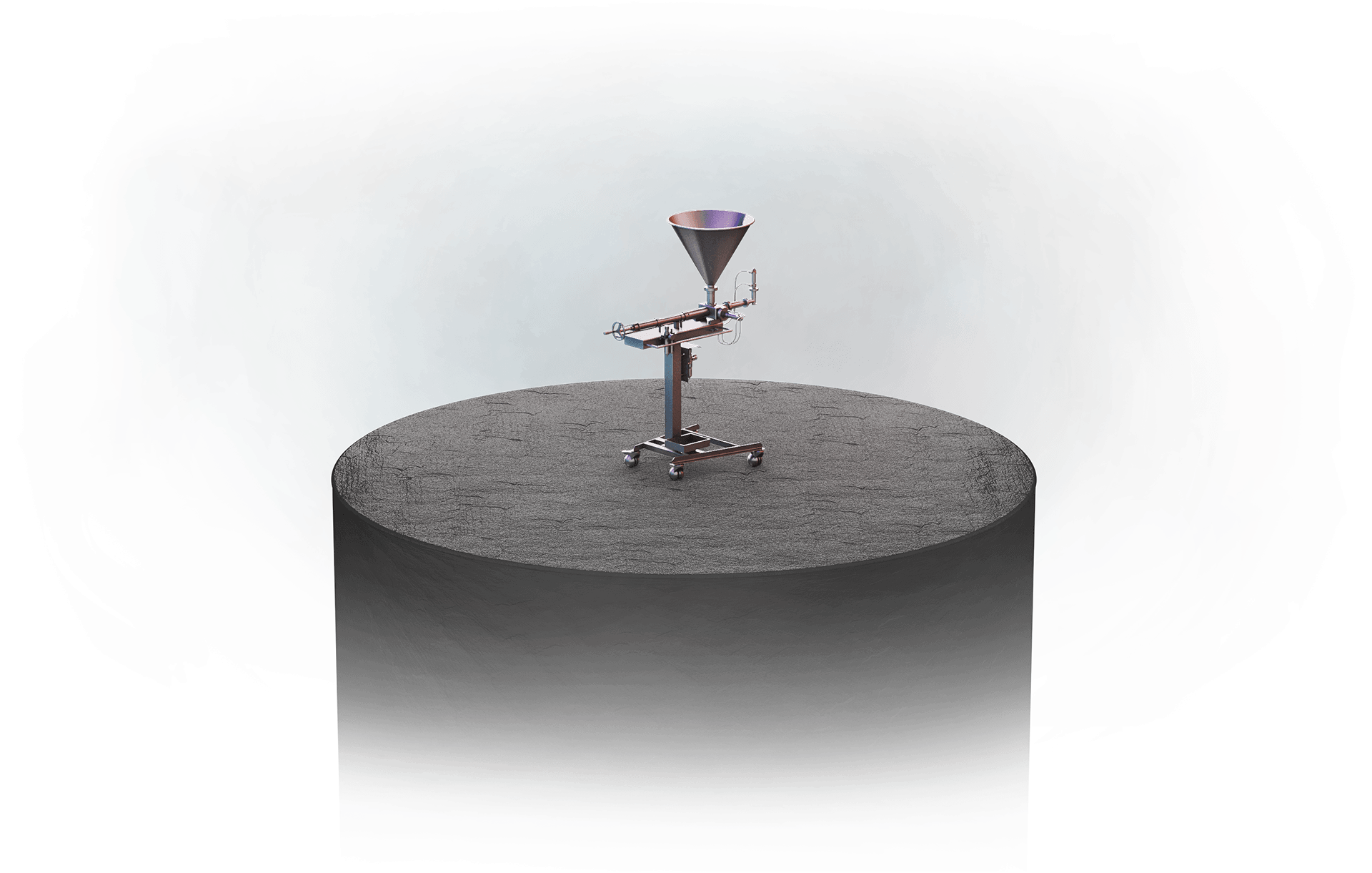

Von der einzelnen Bratlinie über Portionierer bis hin zu unseren vollautomatischen Komplettanlagen – profitieren Sie von bester HOJA-Qualität „Made in Germany“.

HOJA-Rundumservice: Rund um die Uhr – Rund um die Welt

Umfassendes Know-How, modernste Technik und die Verwendung von qualitativ hochwertigsten Komponenten garantieren die besondere Langlebigkeit unserer Anlagen. Und wenn eines Tages doch mal ein wenig Service nötig wird, dann sind wir sofort für Sie da – oder unsere Enkel.

Ob remote per Fernwartung oder mit einem Techniker vor Ort: Unsere multilingualen Experten unterstützen Sie bei Ihren Anliegen. Egal zu welcher Tages- oder Nachtzeit.

Das muss man gesehen haben.

Weil Bilder bekanntlich mehr sagen als Worte, haben wir hier gleich ein paar hundert für Sie. Sehen Sie selbst, wie unser vollautomatischer DRL3000E am laufenden Band geschmackliche und optische Leckerbissen produziert.

Auf den Geschmack gekommen? Dann besuchen Sie uns doch in unserem Technikum und probieren auf 500m² all unsere Anlagen aus. Wir freuen uns auf Sie!

Vertrauen Sie denen, die auf uns vertrauen:

Wir haben eine HOJA DRL3000 mit NGT6-5 Nachgartunnel für Fleisch, Hackfleisch und Geflügelprodukte usw. gekauft.

Die Hohe Produktqualität ist der Hauptgrund für die Entscheidung für eine HOJA Bratlinie, die Produkte haben Restaurantqualität im industriellen Maßstab.

HOJA Linien erlauben uns Sous-Vide Qualität, nur viel günstiger. HOJA Maschinen sind sehr gut und sehr zuverlässig. Der HOJA Service ist schnell und zuverlässig. Ich kann HOJA Maschinen und Service voll und ganz empfehlen.

Wir würden immer wieder eine HOJA Bratlinie kaufen.